|

| How can we sew, craft and live more sustainably? |

Are you someone in search of a new hobby? (As opposed to someone "not needing"

another hobby. 😉)

If so, is there such a thing as a "bad" hobby? Maybe one that's not so great

for the environment or not sustainable? Does your favourite pastime pass

muster for being (somewhat) green?

About four years ago, I became aware of a craft called

diamond painting. A friend was gifted with a kit and she completed it as part of her pandemic

pastimes (photo below).

It didn't occur to me at the time, but what an environmentally unfriendly

hobby it seems to be!

For those who don't know what diamond painting is, it involves sticking

tiny coloured plastic gems (called "drills") onto a coded mat to create

sparkly pieces of art. It's essentially a plastic version of paint by

numbers that produces a finish resembling cross stitch.

|

| An example of diamond painting done by a friend... |

Those who are strong supporters of the craft say that the detailed

attention required to do it has a calming effect on them and thus improves

mental health. Personally, however, I can't get over the fact that someone

actually invented yet another way to introduce millions upon billions of

tiny bits of plastic – contained in small plastic bags, sorted by colour,

no less – into our lives.

Not for me, and to be totally honest, I usually find the results gaudy and

"unhangable". (My other half was given one as a thank you gesture. He had

told the crafter that he liked it, but it's still rolled up in its box, as

there's no way in the opposite of heaven that it's going up on our wall.)

Mental health benefits aside, diamond painting doesn't seem to qualify as

a sustainable hobby.

On the other hand, whenever I do a search for "environmentally friendly

hobbies", sewing is almost always included in the results.

More and more, it's due to the fact that sewers are sourcing supplies in

thrift and second-hand stores... and their own closets. (As for sewing

machines, they've always been common finds in garage sales and the like,

not to mention that you can sew by hand.)

But sewing is not without its environmental controversies, apparently.

Last fall, someone posted a comment on a YouTube video, strongly

admonishing "the bag world" for not acknowledging the problem of plastics

in making bags and purses, particularly as it applies to using vinyl as

the material of choice. This person thought that pattern designers should

be taking more leadership in discouraging the practice.

|

| Printed vinyl called Colorful Heart (by ONEART)... |

Apparently, apart from the usual faux leathers that have been around

forever, there are now all sorts of clear printed vinyls – called

TPUs: thermoplastic polyurethanes – that one can sew with; or more

properly, with which one can sew.

I've not made a bag entirely out of vinyl in years, but I do own a small

supply of (clear) vinyl that I sometimes incorporate into my sewing

projects. Most of it's repurposed, so I'm not so much contributing to the

problem per se, but I get the concern over how introducing more options

into the marketplace isn't necessarily a good thing. (That doesn't address

the ever-increasing practice of sports arenas and stadiums mandating "see

through" bags, but I digress.)

|

| Printed cork fabric called French Symbol (by SorenCut)... |

Fortunately, there are always better options when it comes to materials

for sewing that are environmentally friendly, even apart from repurposing

existing textiles. If being transparent is not a requirement, a material

that has a similar texture to vinyl/faux leather that is a more

sustainable choice is

cork.

In terms of cost, there doesn't seem to be a whole lot to differentiate

the two; a 12" x 53" cut of the TPU is about $23 (CDN) and a 12.5" x 52.5"

cut of the cork is about $26 (CDN). That said, most selections of cork are

always going to appear a bit muted compared to the colourful vibrancy

available in vinyl. I say most, because there are selections like

this one below that might convince you to try cork for your next project.

|

| Image courtesy of frameyourbag on Etsy... |

This particular piece is smaller than the others at only 26.77'' x 19.69"

– and sells for about $19 (CDN) – but it is definitely more colourful than

the usual variants of cork.

There is also an increasing movement among established sewers to "sew down

the stash." I don't know the actual numbers, but let's say that many

people have purchased fabric over their lifetimes, just to have it. Sewing

down your stash simply means that you will not buy new fabric until you

use up your own supply.

Gardening, in general, is another widely recommended sustainable, environmentally friendly hobby.

I really dislike outdoor gardening, but the indoor variant that hubby

started a couple of years ago has rubbed off on me... somewhat. I must

admit that it is tremendously rewarding to see seed, dirt, light and water

combine to grow actual food.

|

| Tomatoes, arugula, spinach, romaine and kale from our indoor garden... |

And all without the messiness of dirty dirt (indoor dirt is

arguably "cleaner", believe me), dealing with insects, and roasting under

the hot sun. I am so not suited for outdoor gardening! We grew

cucumbers along the side of our house last summer, and for a period of

several weeks, I refused to look at them. We had had an explosion in the

mosquito population and just venturing out onto the lawn next to the

garden was sure to provoke an assault by those pesky buggers.

|

| Emerging carrots... |

Inside, I'm able to put my hands into the actual plantings and fiddle with

leaves without fear of finding a huge spider climbing onto my fingers.

(Although, we have have had aphid problems, so it's not all bug

free.). I'm not sweating in the heat. I've heard that some folks like the

whole experience of "being at one" with nature when they garden in the

traditional sense. They are welcome to it.

Scrapbooking Without Supplies

In the three or four years prior to starting this blog, I was very much into virtual scrapbooking. It was a relatively environmentally friendly hobby, quite in contrast to the ultra expensive, material-laden, and ultimately wasteful version of scrapbooking that was all the rage in the early 2000s.

|

| Two pages from a digital scrapbook that I made after a Mediterranean cruise... |

Digital scrapbooking allow you to scatter various embellishments over your

pages just as you would with physical scrapbooking; they're just not

tactile "things" with actual texture and substance. Words and text – in

various fonts – can be added anywhere, photos can be sized and arranged

and creatively edged without cutting, and there is virtually no end to the

types of paper you can select for the background.

As a bonus, you can also use any one of your own photos as the background

"paper" (see example at left), which you wouldn't be able to do easily

with physical scrapbooking.

After completion, your work can be printed out or left as an electronic

file. I don't know what today's preferred apps might be for digital

scrapbooking (it might simply still be called a photobook service),

but I used Shutterfly back in the day for at least two of my

books. (Wait for a sale before printing and you can usually get up to 50%

off no matter what resource you use.)

With digital scrapbooking, there is no mess, no need to hoard supplies,

and you can indulge your creative efforts without lugging around huge

boxes. (There are still scrapbooking events – conventions – that

crafters can attend, although they are not as popular or prevalent as

they were in their heyday.) And unless you print out every book you

make, you also don't need to find a spare room in your house to store

the actual scrapbooks that no one will want in thirty years.

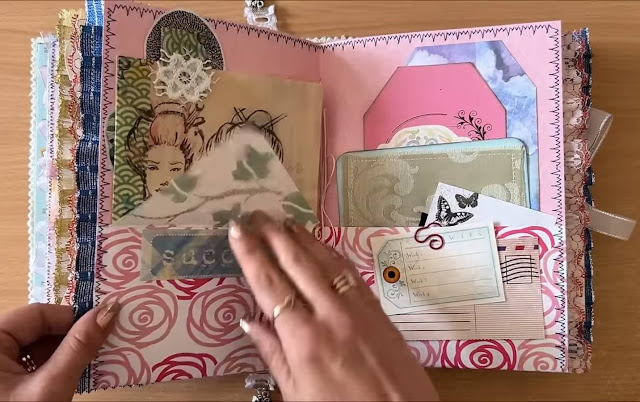

Journaling

Which leads us to the topic of my most recent post, journaling. Whether a junk journal like what's been occupying my time, or an art

journal, or a travel journal, or just a day to day diary journal,

journaling is usually considered a sustainable hobby.

|

| Harvestng Spoonflower packing slips and cards for my jumbo junk journal... |

At the bare minimum, all you need is something to write on and something

to write with. With junk journals, art journals and travel journals, you

just populate the pages with appropriate ephemera, none of which you

need to buy... it's kind of like scrapbooking the way it was done in

the "old days". In the sense that these types of journals encourage reuse

of things that might otherwise be thrown away, they would definitely

qualify as being environmentally friendly. (Natasha at

Treasure Books has a video showing how she embellished an

entire journal using just an old magazine. Just yesterday, I harvested two images out of an Avon catalogue for my journal.)

Project JJJ Update

Speaking of, for those of you curious about my progress on the

JJJ project, you can do a virtual flip through of it (of the first

signature, in any case) in PDF format

here.

Reading, Writing & Stimulating Conversation

This last section is sort of a personal aside. I have always enjoyed

reading and writing and it suddenly occurred to me that they are quite

sustainable activities to enjoy: they cost virtually nothing.

During my ongoing search for quotable quotes for my junk journal, I came

upon a bunch relating to introverts. It may not surprise you

to learn that I am a die hard introvert who always plans her escape from

large gatherings before arriving at them. Introverts are not automatically

shy nor socially inept, they just find being in large groups of people

draining and need time alone to re-energize. (I regularly tell people that

there are only a handful of individuals in this entire world with whom I

can spend more than five hours at a time.) Anyway, it turns out that

reading and writing are – no surprise here – popular hobbies for

introverts.

The third item in the heading above may appear to you to be an outlier for

introverts, but yes, we love one on one conversations. In point of fact,

that entire heading is taken from my first real resume. In

lieu of extensive work experience, we were told to list some hobbies. I

quite correctly assumed that the description of "stimulating" would

attract attention and invite questions.

|

| Courtesy of BrainyQuote.com... |

I was at a fair sized gathering last month and had conversations with five

people whom I had never met before. Out of the five, one was truly a great

conversationalist, another was good. The remaining three... well, let's

just say that I don't know if they ended up learning anything about me

after our talk, beyond what little I offered up myself. (I know stuff

about them, because I asked.) I went home and wrote in my journal, "I love a great conversation, but most people don't know how to have

one."

In the big scheme of things, learning and mastering the give and take of

meaningful conversation is a rewarding and sustainable hobby for everyone.

What do you think?